If you are considering about fabric testing, you might gather a large amount of information. How to test and analysis fabric properties? The article contains all you need to understand. You will get to know these performance related to sports fabrics: Breathability, Moisture Permeability, Heat Resistance, Moisture Resistance, and Moisture Management.

In the field of sports and casual wear, the thermal and moisture comfort of textiles is crucial as it directly affects the wearer’s comfort and health. With growing consumer focus on health and comfort, the demand for fabrics with good thermal and moisture comfort is increasing. Researchers have conducted extensive studies to improve key factors such as breathability, moisture permeability, heat resistance, moisture evaporation rate, and liquid water management.

While research on thermal and moisture comfort in clothing has made progress, studies on the comfort of wet fabrics are still incomplete. Most evaluation methods and testing devices focus on fabrics in a dry state, with limited research on their performance when wet. After intense exercise, clothing can become heavier or even soaked due to moisture buildup. Therefore, the moisture absorption and quick-drying abilities of fabrics are especially important for maintaining comfort.

Thermal Comfort of Fabric Testing

Basic Performance of Fabric Testing

Fabric surface density is tested following FZ/T 70010-2006 “Determination of Dry Mass per Square Meter of Knitted Fabrics”. Fabric thickness is measured using a thickness tester according to GB/T 3820-1997 “Determination of Thickness of Textiles and Textile Products”. Each measurement is repeated 10 times, and the average value is calculated. The porosity of the fabric is determined using the following formula: P=(1-G/pd)/100%

Breathability of Fabric Testing

Breathability is tested according to GB/T 5453-1997 “Determination of Air Permeability of Textile Fabrics” using a fully automatic air permeability tester. Measurements are taken 10 times at different locations on each fabric, and the average value is calculated. Higher breathability values indicate better air permeability. For sports and casual fabrics, better breathability helps release heat and moisture from the body into the air, providing a comfortable feeling.

Moisture Permeability of Fabric Testing

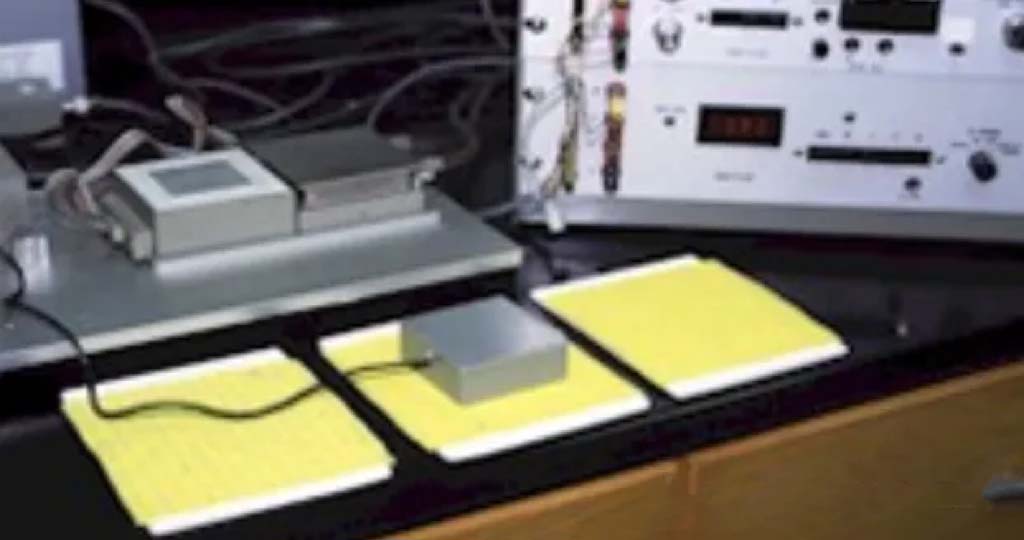

Moisture permeability is tested using a fabric moisture permeability tester according to **GB/T 12704.2-2009** *”Textiles – Test Method for Moisture Permeability of Fabrics – Part 1: Hygroscopic Method”*. Three samples are taken from each fabric for testing, and the average value is calculated. Higher moisture permeability values indicate better moisture permeability. The moisture permeability rate is calculated using the following formula: T=24△m/St

Thermal Insulation of Fabric Testing

Thermal insulation is tested using a flat-plate insulation tester according to **GB 1048-1989** *”Testing Method for Thermal Insulation of Textiles”*. Three samples are taken from each fabric to calculate the insulation rate and thermal conductivity, and the average value is recorded.

Fabric Testing of Instant Cool-touch Performance

According to **GB/T 35263-2017** *”Testing and Evaluation of Instant Cool-touch Performance of Textiles”*, the heat flux of the sample is tested using a contact thermal sensation tester. Five random positions on the backside of the sample are tested, and the average value is calculated to determine the cool-touch coefficient.

Fabric Testing of Thermal Resistance

According to **GB/T 11048-2018** *”Physiological Comfort of Textiles – Determination of Thermal and Moisture Resistance Under Steady-State Conditions (Evaporation Heat Plate Method)”*, thermal resistance is tested using a thermal and moisture resistance tester. The sample size is 35 cm x 35 cm, and the test is repeated three times, with the average value taken. The higher the thermal resistance of the fabric, the lower the heat transfer coefficient, resulting in better insulation, which reduces heat loss during physical activity.

Fabric Testing of Moisture Regain

According to **GB/T 9995-1997** *”Determination of Moisture Content and Moisture Regain of Textile Materials – Oven Drying Method”*, a ventilated oven is used to dry the samples, and the moisture regain of the samples is then tested.

Fabric Testing of Moisture Wicking

According to **FZ/T 01071-2008** *”Test Method for Capillary Effect of Textiles”*, the liquid capillary rise height of the sample is measured using an automatic water absorption speed tester. Three samples are taken from each fabric, and the average liquid capillary rise height is calculated in both the warp and weft directions.

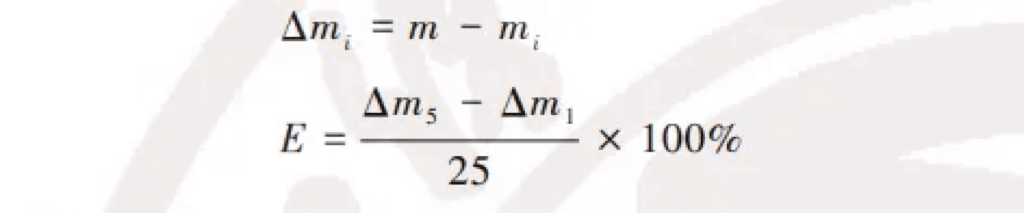

Fabric Testing of Moisture Evaporation Rate

According to **GB/T 21655.1-2008** *”Textiles – Assessment of Moisture Absorption and Quick Drying – Part 1: Single Test Method”*, the moisture evaporation rate of the fabric is tested. A 0.2m water droplet is placed on the fabric surface, and the fabric’s weight is measured at 5, 10, 15, 20, 25, and 30 minutes. The test is repeated 5 times, and the average value is taken. The moisture evaporation rate (E) is calculated using the following formula:

Fabric Testing of Liquid Moisture Management

Liquid moisture management is tested using a liquid moisture management tester, according to **GB/T 21655.2-2019** *”Textiles – Assessment of Moisture Absorption and Quick Drying – Part 2: Dynamic Moisture Transfer Method”*. The tester measures the fabric’s water absorption time (WT) for both the wet surface (T) and the permeable surface (B), the maximum wet radius (MWR), liquid water diffusion time (SS), and absorption rate (AR). These measurements are used to calculate the cumulative one-way transfer capacity (0WTC) and overall moisture management capacity (OMMC), showing how well the fabric manages liquid moisture, especially on the side closest to the skin. All results are rated on a scale of 1 to 5. For each fabric, 10 samples of 10cm x 10cm are prepared, with 5 samples tested before washing and 5 after washing. The results are averaged.

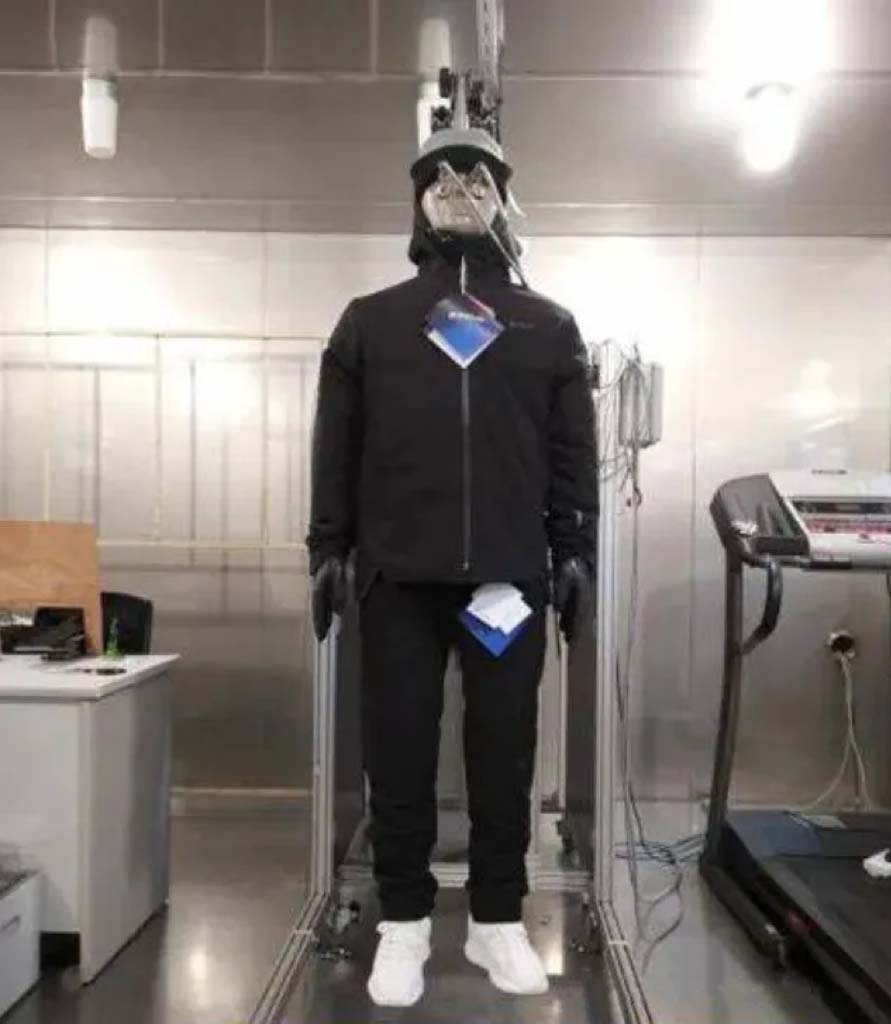

Sweating Thermal Manikin of Fabric Testing

The sweating thermal manikin test simulates how clothing conducts moisture when the human body sweats, either in a resting or active state. The manikin has multiple body areas that can be controlled separately, with each area able to measure skin temperature, heat flux, and equivalent temperature. Additionally, the manikin supports different postures and movements, such as standing, sitting, and walking, and can even include a breathing system to simulate airflow caused by breathing. The key indicators for testing fabric thermal and moisture comfort using the manikin are moisture resistance (Re), moisture permeability, and thermal resistance (Rd).

Performance of Different Fiber Fabrics

1. Moisture-wicking fiber fabrics have the highest thermal and moisture comfort scores, followed by polyester fabrics, while cotton-blend fabrics perform the worst. This shows that the material greatly affects thermal and moisture comfort. Fabrics made from moisture-wicking fibers offer the best thermal and moisture comfort. The reason is that these fibers are made of polyester with a special cross-section, which has a high surface area and grooves. These grooves use capillary action to effectively transfer moisture, providing excellent moisture wicking, permeability, and breathability. On the other hand, cotton-blend fabrics have poorer thermal and moisture comfort due to their higher moisture regain, which gives them good moisture absorption but poor moisture wicking ability.

2. 100% polyester mesh fabrics and moisture-wicking fiber fabrics both have a mesh structure, which gives them strong moisture transfer ability and good heat transfer performance. They can effectively transfer the heat and moisture produced by the body during intense exercise to the fabric’s outer surface, keeping the skin and fabric dry. These fabrics are suitable for hot environments or situations where heavy sweating occurs after intense exercise, making them ideal for moisture-wicking and quick-drying clothing. Among them, moisture-wicking fiber fabrics perform even better and are the top choice for moisture-wicking sportswear.

3. Polyester fabrics and moisture-wicking fiber fabrics both have strong heat and moisture transfer abilities, which help keep the inside of the clothing well-ventilated and dry. They are suitable for making regular sportswear. By reducing the fabric thickness and surface density, their thermal comfort performance can be improved.

4. Cotton, cotton blends, polypropylene viscose blends, and nylon spandex blends have average moisture transfer abilities and good or average heat transfer abilities. They are suitable for making sports and casual wear.

5. Nylon spandex blend fabrics have poor moisture transfer ability but very strong heat transfer ability. They have a smooth, cool surface with high heat transfer and cool-touch coefficients, and the fabric has good elasticity. These fabrics are suitable for indoor summer workouts with little sweating, such as making yoga wear.

6.Cotton-blend fabrics that are not treated for moisture-wicking and quick-drying. It has poor heat and moisture transfer abilities. While cotton blends have good skin feel and moisture absorption, they do not wick moisture or allow breathability well. This causes sweat to be absorbed by the fabric and not released quickly, leading to a sticky and cold feeling, which affects comfort. Therefore, they should be avoided.

Choosing Fabrics for Thermal Comfort

Fabric Selection for Summer Clothing

Summer clothing generally requires lightweight and loose fabrics to reduce heat resistance. The fabric surface should be smooth with high reflectivity to absorb less radiant heat. It should also have good moisture absorption, heat dissipation, moisture release, and breathability. Therefore, lightweight, thin fabrics with low fuzz, high twist, good elasticity, such as fine linen yarn fabrics, as well as silk, rayon, pure cotton, and polyester-cotton fabrics, are ideal choices for summer wear.

Fabric Selection for Winter Clothing

Winter clothing focuses on warmth and wind protection, especially for outerwear. The fabric should have a low thermal conductivity, meaning it should have high thermal resistance and a larger amount of trapped still air while being less breathable. Thus, fabrics with low breathability, thickness, and tightness, or even coated fabrics, are preferred for winter wear.

Methods to Improve Thermal Comfort in Textiles

Improving the thermal comfort of textiles is a multifaceted process involving material selection, fiber structure design, fabric construction, and finishing technologies. Below are some of the main methods and strategies:

Radiation-Temperature Regulating Fabrics

By controlling the fabric’s infrared permeability to the human body, its infrared emission rate to the sky, and its solar reflectance, these fabrics manage the heat radiation between the body, clothing, and the environment, achieving either cooling or warming effects.

Phase Change Temperature-Regulating Fabrics

Using phase change materials (PCMs) that absorb or release heat when temperature changes, these fabrics help regulate temperature and maintain comfort on the body’s surface.

Smart Response Fabrics

Incorporating stimuli-responsive polymers (SRP), these fabrics automatically adjust their structure in response to changes in environmental temperature and humidity, enhancing heat exchange and improving thermal comfort.

Thermal Conductive Fabrics

By using materials with high thermal conductivity or altering fiber structure, these fabrics increase heat transfer efficiency, allowing heat to flow from the body to the environment, helping to cool the wearer.

Energy Conversion Device-Integrated Temperature-Regulating Fabrics

Micro energy conversion devices, such as small fans or liquid cooling systems, can be integrated into fabrics to achieve personal thermal and moisture management.

Moisture Management Fabrics

Fabrics that quickly absorb, transfer, and evaporate sweat can reduce discomfort from sweat accumulation and improve thermal and moisture comfort for the wearer.

Fiber and Yarn Innovations

Using fibers with excellent moisture-absorbing properties, such as modified polyester, and enhancing hydrophilicity through surface modification can improve thermal and moisture comfort.

Fabric Structure Design

Optimizing fabric structure, such as using moderately tight fabrics to maintain appropriate porosity, stores still air to enhance warmth while ensuring good moisture transfer.

Post-Finishing Technologies

Finishing processes like moisture-wicking and moisture-regulating treatments improve the fabric’s hydrophilicity or hydrophobicity, influencing the adsorption, diffusion, and evaporation of sweat.

Functional Fabric Development

Developing fabrics with specialized functions, such as one-way moisture-wicking fabrics or waterproof and breathable membranes, to meet different environmental and user needs.

Through these methods, the thermal and moisture comfort of textiles can be significantly improved, meeting consumer demands for high-quality living and driving technological progress and innovation in the textile industry.

Relevant Testing Standards

1. GB/T 39605-2020: Clothing Moisture Resistance Testing Method – Sweating Thermal Manikin Method

This standard is applicable for testing the moisture resistance of a full set of clothing in an upright, stationary state. It can also be used for testing the moisture resistance of individual upper or lower garments, as well as under different wind speeds, body postures, and movement speeds.

2. GB/T 18398-2001: Clothing Thermal Resistance Testing Method – Thermal Manikin Method

This standard is used to test the thermal resistance performance of clothing.

3. ASTM F2370: Standard Test Method for Measuring Clothing Evaporative Resistance Using a Sweating Manikin

This American standard provides the method for measuring the evaporative resistance of clothing using a sweating human model.

4. ASTM F1720: Standard Test Method for Measuring Insulation of Sleeping Bags Using a Heated Manikin

Another American standard that provides a method for measuring the insulation properties of sleeping bags using a heated human model.

5. ASTM F1291: Standard Test Method for Measuring the Thermal Insulation of Clothing Using a Heated Manikin

This is an obsolete American standard for measuring the thermal insulation properties of clothing using a heated human model.

6. GB/T 33658-2017: Indoor Human Thermal Comfort Environment Requirements and Evaluation Methods

This Chinese national standard involves the thermal comfort performance requirements and evaluation methods for indoor environments.

7. GB/T 43573-2023: Clothing Heat Dissipation Performance Testing Method – Sweating Thermal Manikin Method

This standard is used to determine the heat dissipation performance of clothing.

These standards guide the testing of various aspects of fabric and clothing performance, such as moisture resistance, thermal resistance, and heat dissipation, to ensure products meet specific comfort and functionality requirements.